Tunnelling FAQs

Work to deliver the Western Harbour Tunnel (excluding the Warringah Freeway upgrade works) will be delivered in two stages.

Stage 1

The tunnel excavation of the southern section is called Stage 1 of the Western Harbour Tunnel (WHT), which includes 1.7km of tunnel connecting Emily Street in Rozelle to Cove Street in Birchgrove. This stage is excavation only and does not include the Tunnel Civil Fit-out (TCF) and tunnel Mechanical and Electrical (M&E) activities.

Stage 2

Stage 2 will see construction of the northern end of the tunnel from Cove Street in Birchgrove, through the harbour to North Sydney. It includes connections to the Warringah Freeway near North Sydney, marine work through Sydney Harbour and the complete tunnel fit out of the entire tunnel alignment.

The contract for Stage 2 is planned to be awarded late 2022, with work to commence in 2023.

John Holland CPB Contractors Joint Venture has been awarded the contract to excavate the first stage of the Western Harbour Tunnel (WHT). The contract involves tunnel excavation only with the contractor for the next stage (between Birchgrove and North Sydney), responsible for Tunnel Civil Fit-out (TCF) and Mechanical and Electrical (M&E) activities.

Tunnel excavation has started for Stage 1 of the Western Harbour Tunnel. Tunnelling commenced on 29 June 2022 in Rozelle.

Tunnelling excavation will begin in the suburbs of Balmain and Birchgrove in 2023 and 2024, respectively. Tunnelling early work, to support the construction of the tunnel, will begin in 2022 in Balmain and Birchgrove.

The detailed design review process considers further information about geological conditions, better design outcomes for motorists, sub-surface structures and constructability.

The detailed final design (released in July 2022 for Stage 1) includes depths and locations of permanent maintenance and ventilation tunnels, substations and temporary access tunnels required during construction. Temporary access tunnels are essential supporting features required to effectively operate the WHT network and their position is reliant on the final location and depth of the traffic tunnels.

Typically for complex major infrastructure projects, the design and construction approach presented in the Environmental Impact Statement (EIS) is at planning stage and is indicative only. The design presented in the EIS is subject to refinement once the Contractor delivering the project has been appointed and is able to carry out further investigations, engineering analysis and construction planning.

In February 2022, we carried out geotechnical and groundwater monitoring in the Rozelle, Balmain and Birchgrove area. Information gathered during this stage was used to help finalise the detailed design of the tunnel alignment and location of supporting structures for the project.

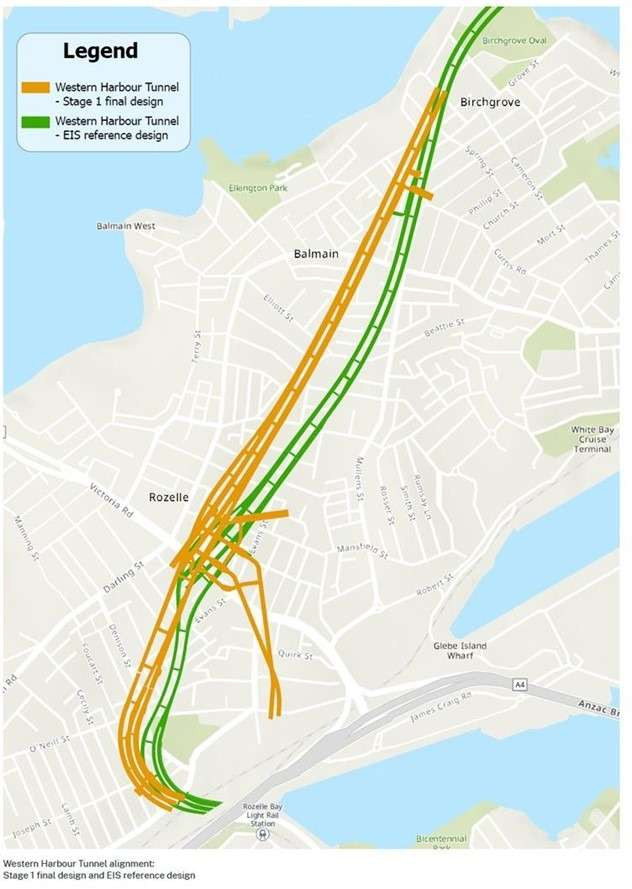

The final tunnel alignment has shifted from what was presented in the EIS, following this detailed design process. In some locations, by up to 70 metres. This was to take advantage of better ground conditions for tunnelling and to provide a straighter route, making it easier and safer to drive.

While the location and depth of some of these tunnels has changed, the overarching impacts assessed under the EIS, are expected to be the same. The location of the final detailed design compared to the EIS reference design is captured in the map over the page.

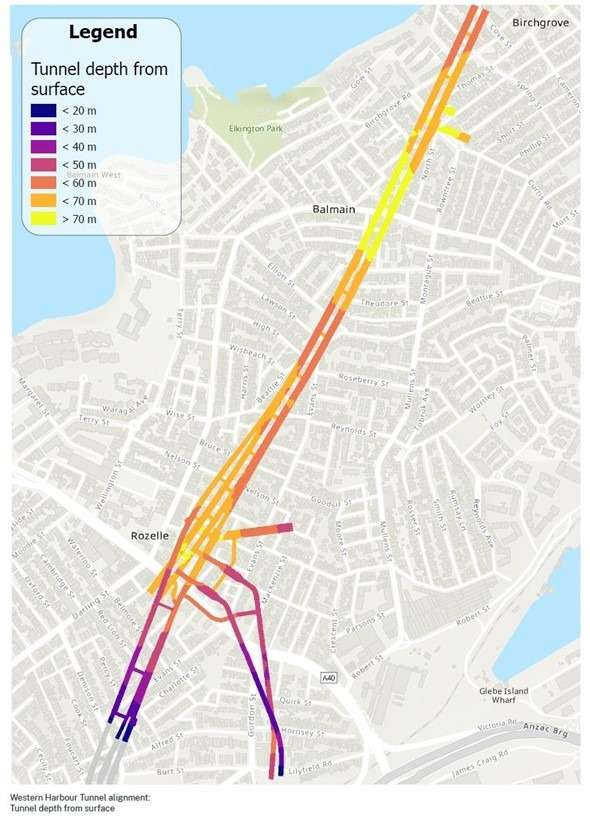

The tunnels are relatively deep, ranging from their shallowest at 15 metres at Emily Street, Rozelle to their deepest at 74 metres at Darling Street, Balmain. We expect most residents to have low to mild level of disruption from tunnelling noise. This is due to the relative depth of these tunnels and JHCPB’s previous local experience with tunnelling. The tunnel depth across the Stage 1 alignment is highlighted in the map below.

Stage 1 of the Western Harbour Tunnel will be excavated in two phases, primarily with a roadheader, an excavation machine that cuts rock in a circular motion suitable for creating the arched shape cavern required for road tunnels. Six roadheaders will be used to excavate Stage 1.

- The first phase involves excavation of the tunnel roof using a roadheader. The crew excavate between 1-5 metres at a time (depending on the design), before installing ground support into the tunnel walls, including rock bolts (metal rods) and shotcrete (sprayed concrete). We generally excavate around 20-25 metres of rock per week.

- The second phase of tunnel excavation involves removal of the tunnel floor using a roadheader or rock hammer. When using a roadheader, this work progresses much quicker than the first phase, at approximately 15-25 metres per On some occasions, we will need to use a rock hammer to excavate the floor. This work will be restricted based on vibration levels in compliance with project approvals.

- Tunnel support activities include drilling, adding extra rock bolts, profiling, installing drainage and laying a new road

The tunnels will be dug by a machine called a roadheader that uses a rotating head on a moving boom, to excavate the rock. Roadheaders have been chosen because they are best suited to digging road tunnels as their arm can create the arched roof shape and a flat base, suitable for road construction.

To support the completed excavation, a rockbolting machine is used to install rockbolts into the tunnel roof. Rockbolts range in length depending on the ground conditions and excavation size. Rockbolts are drilled, tensioned and injected with grout to increase the strength of the tunnel roof.

Shotcrete is then applied to keep the tunnel roof and sides in place. The amount of shotcrete applied depends on the ground conditions and the excavation size.

Moxie’s are specialized dump trucks used to transport spoil inside the tunnels to the acoustic shed. The spoil is then loaded onto large trucks with trailers and taken off site to approved spoil tip sites. Receiver sites for spoil for the Western Harbour Tunnel Stage 1 are located mainly out west and include future developments.

The size of the tunnel will determine the length of time and number of times the roadheader will need to pass under a property. People may notice when the first phase of tunnelling excavation occurs, which is the excavation of the roof. This can take between 2-4 weeks. The second phase may be noticeable for one week. If we’re excavating a wider section of tunnel, we could be in the area for up to three months.

The project has approval to carry out tunnelling activities 24 hours per day, seven days a week. This schedule is provided for two reasons:

- significantly reduce the overall timeframe taken to excavate the tunnels and reduce the impact to residents

- allows ground support to be immediately applied following excavation (safety requirement)

*Tunnelling for Stage 1 will mostly take place between 6am Monday and 6am Saturday (24 hours a day), giving residents a 2-night respite on weekends. As needed, tunnelling activities may take place inside the tunnels from 6am Saturday to 6am Monday but we will notify before this occurs.

Ground material will be loaded into trucks inside the tunnel (spoil loading), limiting noise impacts to nearby residents. Trucks will drive out of the WHT portal onto City West Link heading to tip sites primarily out west. There is no spoil haulage planned on Victoria Road and through the Birchgrove peninsula. Spoil haulage and concrete deliveries are required to happen at night for ground support to be installed immediately after excavation.

The Western Harbour Tunnel Stage 1 is mostly being constructed through Hawkesbury sandstone. This is a robust and consistent rock structure that is ideal for tunnelling due to its uniform strength. This is the same ground conditions that the Rozelle Interchange JHCPB team had when excavating under Leichhardt, Rozelle and Lilyfield.

Settlement is the movement of the ground, generally caused by changes in stresses within the earth.

Excavation of tunnels will almost always cause some settlement. Tunnel-induced settlement is the result of the ground relaxing around newly excavated area and occurs at the time of excavation and the weeks proceeding.

Groundwater drawdown is when groundwater flows into the tunnel causing ground at the surface to lose volume. This form of settlement typically occurs very slowly over the lifetime of the project.

Ground movement does not necessarily result in property damage. Buildings generally experience ground movement naturally through environmental changes such as seasonal climate variations, vegetation (tree roots), structural effects (different building types of age of construction) or ground effects (reactivity to soil).

The Department of Planning & Environment (DPE) has provided acceptable limits for settlement. These limits permit maximum of 30mm ground movement for two story buildings and less, 20mm ground movement for three story buildings and more. There are also settlement limits provided for parks and roads.

During the design development phase, a geotechnical model is created to understand the ground and hydrogeological conditions along the tunnel alignment. The report informs the design to ensure that settlement levels remain within these thresholds. In most instance the tunnels are designed to have settlement limits much lower than the acceptable limits.

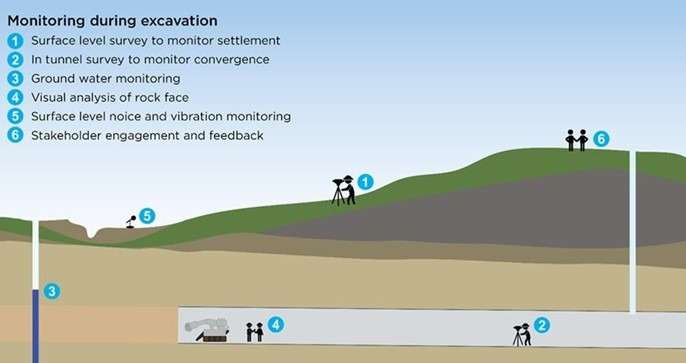

During excavation, the team use a conservative trigger (green, amber, red) system to address changing ground movement levels. Geotechnical engineers map the tunnel rockface at every excavation advance to measure any settlement and this information is incorporated into a daily planning meeting with construction teams.

Monitoring occurs on the surface and inside the tunnel throughout excavation, as shown in the image below. Residents may notice prism markers being installed on roads and footpaths by our survey team ahead of tunnelling in an area. These prisms are used to monitor potential ground movement throughout excavation. We will monitor these prisms on a daily basis at the location of our tunnelling activities.

We understand there is concern about the potential for vibration and settlement impacts from tunnelling works. Ground movement does not necessarily result in property damage, in fact it is highly unlikely. Buildings experience ground movement naturally through environmental changes such as seasonal climate variations, vegetation (tree roots), structural effects (different building types of age of construction) or ground effects (reactivity to soil).

To give further peace of mind to local residents and businesses, all properties within a zone on the surface equal to 50 metres from the outer edge of the underground tunnels will be offered a property condition survey before and after the project has finished construction, at the request of the property. The project strongly recommends property owners accept the offer to have one completed. The PCS is free to residents, and will provide a photographic baseline for comparison if you have concerns about property damage that you believe was caused by construction activity.

A PCS involves a visual inspection of the interior and exterior of your property, including any outside structures such as balconies, sheds, driveways, pathways, swimming pools, fences and retaining walls by a qualified surveyor.

The report will also include photographs to provide an accurate record of the current condition of the property and will record any noticeable defects. Inspections are scheduled to take place during daylight hours to accurately record the condition of the property’s exterior.

The project will send out pre-construction PCS to residents who live within 50 metres of the Western Harbour Tunnel alignment 8-12 weeks before tunnelling under your property. The PCS is a visual report of your home's current state, complete with images of any existing damage or features. You will be given a copy of the report. The project will make three attempts via letter to offer a PCS. If you’ve subscribed to our email distribution list the project will attempt to also contact you via email.

The Western Harbour Tunnel Stage 1 is a sperate project from others in the area and is being carried out by a different construction contractor. You will need a separate PCS for your property and each project will notify separately.

Residents should contact the project as soon as possible to begin the process of filing a property damage claim. You do not have to wait until the post-construction PCS is complete to file a claim for property damage. The property damage team will then contact you and walk you through the property damage process.

If you’re dissatisfied with the project's decision on your damage claim, you can request a review, which if not satisfied will allow your claim to be reviewed by an Independent Property Impact Assessment Panel (IPIAP) through Transport for NSW. The panel is made up of geotechnical and engineering specialists who have been approved by the Department of Planning, Industry and Environment (DPE).

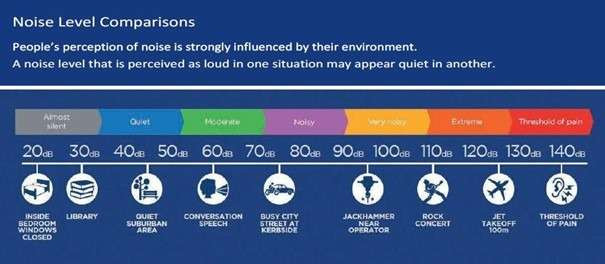

Generally, noise and vibration impact from tunnelling is most noticeable when we are closest to a property, increasing on approach and reducing as we move away. The deeper the tunnel the less likely you are to hear excavation (generally from below 30 metres is low noise impact), so 60-70 metres will be barely audible. The sounds you may hear during tunnelling include:

First phase:

- roadheader excavation sounds like an old refrigerator humming which will occur 24/7

- rock bolting creates a temporary drilling As this drilling noise stops and starts, it can be more noticeable to residents

Second phase:

- daytime rock hammering will create a repetitive tapping sound varying in impact depending on your property's location to the

Tunnel support activities:

- including rock bolting and drilling create a temporary drilling As this drilling noise stops and starts, it can be more noticeable to residents.

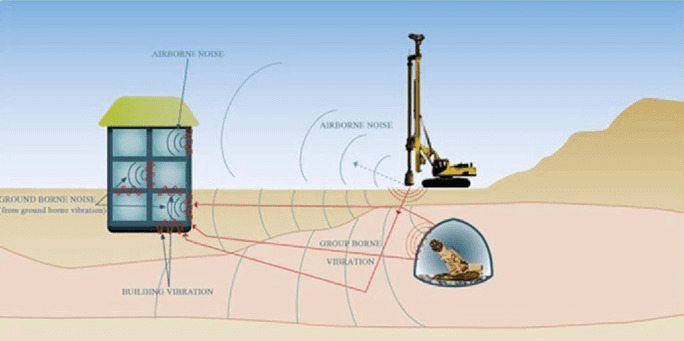

Ground borne noise (GBN) is the conversion of ground-borne vibration (GBV) which passes through the ground and into a built structure, resulting in audible noise levels. When assessing GBN, there is a correlation between ground borne noise and ground borne vibration.

We measure noise in decibels. Noise is measured, predicted, and assessed in accordance with the relevant legislative guidelines. Our noise modelling considers the local ground conditions and construction methodologies. If we predict you may experience noise levels over the guidelines, we will implement additional mitigation measures and monitor noise levels. Our assessments are conservative and always assess the worst-case scenario. We often find when we are working the noise generated is less than we predicted. For information about noise see our managing noise page on our portal.

While we are building, we will monitor noise and vibration to make sure it meets the appropriate guidelines. Throughout construction we regularly monitor noise at different times of the day and night to ensure noise is within our predicted noise levels. This monitoring lets us know if we need to change our construction methods, adjust our mitigation measures, or adjust the noise model. All our work will be carried out in line with the project’ Conditions of Approval, Environment Protection Licence and Construction Environmental Management Plan which are overseen by the Department of Planning and Environment (DPE) and NSW Environment Protection Authority (EPA).

In line with project approvals, respite is provided if a property is predicted to have noise levels exceeding 45 decibels for more than two consecutive nights. Due to the tunnels being so deep, there are currently no properties along the WHT Stage 1 alignment that are expected to reach noise levels of 45 decibels.

If noise modelling indicates your property meets these criteria, the project will proactively contact you to discuss the available options ahead of the work starting.

The Environmental Protection Authority (EPA) and Transport for NSW have informed, consulted, and have approved these limits and respite thresholds. Therefore, the project strictly adheres to the above criteria to avoid inequity amongst properties along the tunnel alignment.

If your property is above an underground tunnel, you will not hear any operational noise from vehicles using the tunnel. For more information about how we manage operational noise can be found at the bottom of the page of our managing noise page.

The Rozelle Interchange project scope included the construction of one WHT ventilation outlet for the project. This ventilation outlet is one of three-cylinder structures on the Rozelle Rail Yard site (sitting above City West Link) that serve as part of a ventilation facility for the WHT, M4 and M5 tunnel portals at the Rozelle Interchange. The second ventilation outlet for WHT is in Cammeray.

The ventilation outlets for the Western Harbour Tunnel are not filtered. Studies have found that filtration systems would not provide any measurable improvement to the air quality in the surrounding community, and as such, there is little to no health benefit for surrounding communities in installing filtration and air treatment systems in such road tunnels.

Filtration does not remove all pollutants from tunnel air so regardless we still need to run ventilation outlets and stacks to protect local air quality. To find out more information please visit You can learn more about ventilation systems, filtration and air treatment systems by visiting chiefscientist.nsw.gov.au or nswroads.work/airquality.