Frequently asked questions (FAQs)

The Western Harbour Tunnel (WHT) is part of the NSW Government’s biggest infrastructure program in history, changing the way people move as our motorways expand to better serve our growing city.

By creating a western bypass of the Sydney CBD, Western Harbour Tunnel will take pressure off the Sydney Harbour Bridge, Sydney Harbour Tunnel, Anzac Bridge and Western Distributor corridors to improve transport capacity in and around Sydney Harbour.

It connects to WestConnex at the Rozelle Interchange, crosses underneath Sydney Harbour between Birchgrove and Waverton, and connects with the Warringah Freeway near North Sydney via a 6.5 kilometre tunnel with three lanes in each direction.

As Sydney continues to grow, faster and more reliable trips are essential to reduce congestion. By creating a western bypass of the Sydney CBD, the Western Harbour Tunnel will take pressure off the Sydney Harbour Bridge, Sydney Harbour Tunnel and Anzac Bridge.

This project is an important part of creating an integrated road and public transport network, which balances the needs of motorists and local communities and provide new levels of access to jobs, recreation, and services such as schools and hospitals.

The Western Harbour Tunnel will provide improved transport connections with quicker access to public transport interchanges. It will enable future opportunities for new direct bus routes between the Inner West and North Sydney.

The Western Harbour tunnel is being delivered in two stages:

Stage 1 was delivered by John Holland and CPB Contractors joint venture (JHCPB) and included construction of the 1.7km southern section of the tunnel from under Emily Street in Rozelle to Cove Street in Birchgrove. Stage 1 work started in June 2022 and was completed in February 2025 when they handed the southern tunnels over to Stage 2 contractor, ACCIONA, to complete the tunnel excavation and fit out.

Western Harbour Tunnel Stage 2 is being delivered by ACCIONA and includes construction of the northern end of the tunnel, with connections to the Warringah Freeway near North Sydney, tunnelling from Birchgrove launch chambers under Sydney Harbour, and delivering the complete tunnel fit out for the project.

The contract for Stage 2 was awarded in late 2022 and early work commenced in May 2023. In November 2023 Stage 2 started tunnel excavation using roadheaders on the north side of the Harbour at Cammeray.

Keep up to date with our progress by checking our Notifications Map.

The Western Harbour Tunnel will provide a new crossing of Sydney Harbour involving twin motorway tunnels connecting the Warringah Freeway near North Sydney with WestConnex at Rozelle Interchange.

With three lanes in each direction, it will take pressure off the Sydney Harbour Bridge, Sydney Harbour Tunnel, Anzac Bridge and Western Distributor corridors enhancing transport capacity in and around Sydney.

Together with the Warringah Freeway Upgrade, there will be improved public transport connections, with quicker access to interchanges and a new, direct connection to North Sydney.

There will also be opportunities for new direct bus routes between the Inner West and North Sydney using the Western Harbour Tunnel.

Construction of the Western Harbour Tunnel will help drive the NSW economy by creating around 7,000 full-time direct jobs.

Transport and Western Harbour Tunnel Stage 2 contractor ACCIONA are committed to creating opportunities for local businesses and suppliers on this major project. In collaboration with industry, the delivery of Western Harbour Tunnel will include the development and implementation of a business capability program to increase the capability and capacity of ANZ Small and Medium Enterprises and social enterprises.

John Holland CPB Contractors Joint Venture (JHCPB) delivered Stage 1 of Western Harbour Tunnel. The contract involved tunnel excavation from under Emily Street, Rozelle, to Cove Street, Birchgrove.

ACCIONA is currently delivering Stage 2 of the Western Harbour Tunnel project.

The $4.24 billion contract to deliver Stage 2 was awarded to ACCIONA in December 2022 following a successful competitive tender process.

The second and final stage of the project includes construction of the northern end of the tunnel, connections to the Warringah Freeway near North Sydney, tunnelling under Sydney Harbour and the complete tunnel fit out.

The procurement process involved inviting tenderers to submit proposals to deliver Stage 2 of the Western Harbour Tunnel, and an extensive period of rigorous investigation and negotiation to determine the preferred tenderer. Click here to read more about the contract award and tender process.

The procurement process involved inviting tenderers to submit proposals to deliver Stage 2 of the Western Harbour Tunnel project, and an extensive period of rigorous investigation and negotiation to determine the preferred tenderer.

Western Harbour Tunnel will be delivered and operated in line with all relevant guidelines and the projects’ planning approvals. As is standard for a major project reporting and auditing mechanisms are in place within Transport for NSW, and externally with Department for Planning, Housing and Infrastructure (DPHI) and other overseeing authorities.

Transport for NSW (Transport) has engaged The APP Group as the Independent Certifier for the Western Harbour Tunnel project. The Independent Certifier will ensure that the project is delivered in accordance with the agreed design document and planning approvals. Transport looks forward to working with The APP Group to ensure that Western Harbour Tunnel is delivered successfully.

Consistent with NSW Government policy, a summary of the Business Case for the Western Harbour Tunnel was released by Infrastructure NSW in May 2020 and is available for download on the Infrastructure NSW website. You can download the summary here.

The Western Harbour Tunnel and Warringah Freeway Upgrade project was approved by the Minister for Planning and Public Spaces in January 2021 following the exhibition of the project’s Environmental Impact Statement (EIS) and release of the Submissions Report.

Stage 1 + 2 - Rozelle to Birchgrove

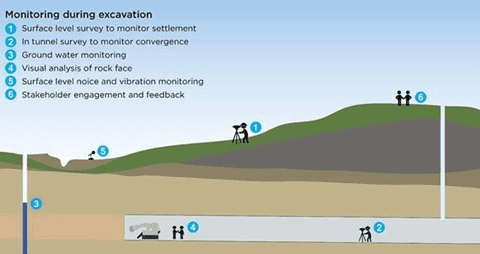

Early work for Western Harbour Tunnel Stage 1 started in February 2022 with geotechnical investigations and ground water monitoring being carried out to help inform the detailed design for the tunnel alignment.

Construction of Stage 1, the southern section of the tunnel, began on 29 June 2022 in Emily Street in Rozelle, and was completed in February 2025.

The tunnels were then handed over to Stage 2 contractor ACCIONA to continue excavation from Birchgrove to Waverton and complete the tunnel fit out.

Stage 2 - Birchgrove to Cammeray

Early work for the second stage of WHT started in May 2023.

The project started roadheader tunnel excavation on the north side of the Harbour from November 2023 at Cammeray. Work will continue for approximately five years.

The Western Harbour Tunnel and Warringah Freeway Upgrade project was approved by the Minister for Planning and Public Spaces in January 2021 following the exhibition of the project’s Environmental Impact Statement (EIS) and release of the Submissions Report.

The Western Harbour Tunnel and Warringah Freeway Upgrade EIS was exhibited for 61 days from 29 January 2020 to 30 March 2020. We received 1,459 submissions. Of these submissions, 18 were received from NSW Government agencies and local councils, and 1,441 from other organisations and members of the public. Further information regarding project history, including the full EIS and Submissions Report can be found here.

From 19 July to 15 August 2023, we invited the community to have their say on proposed changes to the way we build the Western Harbour Tunnel under Sydney Harbour, outlining a modification to the approved Western Harbour Tunnel project to change the construction methodology for crossing under Sydney Harbour between Birchgrove and Waverton from the approved Immersed Tube Tunnel (IMT) method to tunnel boring machines (TBMs). During this submission period we held four information sessions and an online information session to support the community in understanding our proposed changes and to encourage submissions to be provided to the Department for Planning, Housing and Infrastructure (DPHI) for consideration.

The Western Harbour Tunnel project will create up to 7,000, full time jobs during delivery.

NSW Government’s Infrastructure Skills Legacy Program sets mandatory requirements for infrastructure agencies to meet minimum targets for skills, training and diversity. Some of these minimum targets that apply to Western Harbour Tunnel include: 20% of Trades Workforce to be Apprentices; 20% of the Project Workforce to be Learning Workers: 2% of the Trades Workforce to be Women: and 8% of the Project Workforce to be Young People.

The Western Harbour Tunnel will be tolled, but the proposed toll level has not yet been determined.

In December 2022, Transport awarded the second and final stage of the Western Harbour Tunnel project to ACCIONA, who will be using tunnel boring machines (TBMs) to construct the section of tunnels under Sydney Harbour.

The use of this methodology means that the temporary construction site at Berrys Bay is no longer required for the project, however the NSW Government is committed to returning the space to the community by allowing the delivery of a new foreshore park much earlier than planned for the benefit of the local community.

In consultation with North Sydney Council (Council) and community representatives, Transport prepared a landscape master plan to transform the former industrial land at Berrys Bay into a foreshore park. The draft master plan was on public exhibition from 30 September to 23 October 2022. The final master plan was released on 8 February 2023.

The detail design for Berrys Bay went on public display through the WHT PDLP (Part 2) - Berrys Bay between 28 July 2025 - 24 August 2025.

The draft PDLP is now closed for community feedback. All submissions received during the public exhibition period will be carefully reviewed and considered in shaping of the final design. The WHT PDLP (Part 2) - Berrys Bay will then be submitted to the Department of Planning, Housing and Infrastructure (DPHI) for approval, in accordance with the WHT project’s Conditions of Approval.

The tunnels are relatively deep. The tunnel starts at a depth of around 15 metres at Emily Street, Rozelle, before going deeper to approximately 50 metres when it goes under Victoria Road. It keeps going deeper to a depth of 74 metres when it passes under Darling Street, Balmain, before starting to rise back to 50 metres when it reaches Cove Street, Birchgrove.

The project has approval to carry out tunnelling activities, including support activities, 24 hours per day, seven days a week.

Tunnel excavation from Rozelle to Birchgrove has been completed, and the next stage of excavation will be when the tunnel boring machines (TBMs) launch under Sydney Harbour in mid-2026.

There is some excavation work occurring in the ventilation tunnels under Rozelle from November 2025 for up to six months.

For more information on this please see our fact sheet.

The project sends an email to all subscribed residents every Friday with the latest work activities in the Inner West. This is the best way to keep track of our work near your property.

You can subscribe to these updates by clicking here.

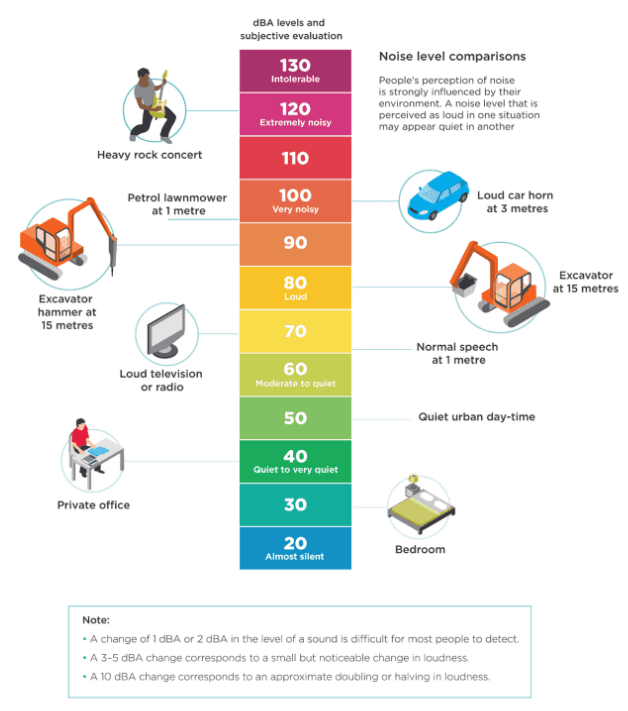

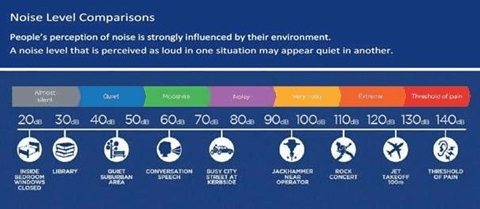

Tunnelling activities can occur 24 hours a day, seven days a week. Noise from tunnelling work is dependent on the depth of the tunnel. The deeper the tunnel the less impact experienced by a property.

You may hear some sound while we are carrying out tunnel fit out activities in the tunnels under Lilyfield, Rozelle, Balmain and Birchgrove, particularly at night when background noise levels are lower.

Tunnel fit out activities include installing power, lighting and ventilation as well as fire safety measures, tolling and traffic management systems known as Intelligent Transport Systems (ITS). Depending on the depth of the tunnel, these activities can be noisy at times. Roadheader excavation sounds can vary depending on a variety of conditions including but not limited to, ground conditions, the make and materials of the dwelling and tunnel depth. Excavation can occur 24 hours a day, seven days a week. Rockbolting creates a temporary drilling noise which occurs intermittently over a 24-hour period. As this drilling noise stops and starts, it can be more noticeable to residents.

The TBM delivery method being used to tunnel under Sydney Harbour removes the need for four temporary construction sites on Sydney Harbour, at Berrys Bay, Waverton, and at Yurulbin Point, Birchgrove.

This is because the TBMs are being assembled underground in Birchgrove to tunnel under Sydney Harbour to Waverton.

Our work sites in the Inner West include:

The Motorway Operations Complex (MOC) at Rozelle Parklands, Lilyfield Road – originally established to support Western Harbour Tunnel (WHT) Stage 1 and the Rozelle Interchange projects. It is now developing the facilities needed to support the construction and future operation of Western Harbour Tunnel.

Glebe Island – this tunnelling support site is the central site for all project workers assisting with tunnelling related activities in the Inner West. It has also been the arrival and storage location for the two tunnel boring machines (TBMs), which arrived by ship in August and October 2025.

Tunnels under Lilyfield, Rozelle, Balmain and Birchgrove – these tunnels have been excavated and fit out activities are underway to prepare the tunnels for operation. Fit out work includes installing systems such as power, lighting, ventilation, and safety infrastructure. Widening of the ventilation tunnels under Rozelle will continue until April 2026. Our tunnel boring machine (TBM) parts are being delivered to the launch chambers under Birchgrove, where they will be assembled and launched in the second quarter of 2026.

We are preparing to install an Intelligent Transport Systems (ITS) network around the Western Harbour Tunnel (WHT) entry and exit portals in City West Link, Rozelle from 29 December 2025.

These systems provide real time information and advanced warning to drivers using the road network and will be critical for the safe and efficient operation of Western Harbour Tunnel when it opens to traffic in 2028. More information can be found here.

Our work in City West Link, The Crescent, and Johnston Street will involve temporary lane and road closures, reduced speed limits, and detours for pedestrians and cyclists. Traffic controllers and signage will be in place to ensure safety, and access will be maintained.

You may notice construction vehicles, noise from machinery, and changes to walking and cycling routes. Additional closures may occur during school holidays, check Live Traffic for updates.

Work in the tunnels under Lilyfield, Rozelle, Balmain, and Birchgrove, is ongoing and includes excavation to widen the ventilation tunnels under Rozelle for the ventilation facilities to be installed from 2026.

Excavation of the two tunnel boring machine (TBM) launch chambers beneath Birchgrove is complete, and we are now receiving deliveries of the TBM parts which will be assembled underground to tunnel under Sydney Harbour in mid-2026.

Extensive tunnel fit-out activities along the tunnel alignment from Lilyfield to Birchgrove will continue until 2027. This includes the installation of power, lighting, ventilation, tolling systems, Intelligent Transport Systems (ITS), drainage, electrical conduits, signage, trenching, paving, and road surface finishing.

The ventilation tunnels under Rozelle are being widened to accommodate the permanent ventilation facilities for the tunnels.

Two ventilation caverns were excavated during Stage 1, however with the change in the project method to use tunnel boring machines (TBMs) under the harbour, each of the two TBMs will require a slurry treatment plant (STP) which are now being installed in these ventilation caverns. They are needed to process and drain spoil excavated by our TBMs as these machines tunnel under Sydney Harbour from Birchgrove to Waverton.

Having the STPs underground minimises the impact on the surface for residents. By widening the existing ventilation tunnels we will be able to fit-out the ventilation facilities while the STPs are operating in 2026 and 2027.

Using TBMs means we no longer require a temporary construction site or cofferdam at Yurulbin Point. As a result, there will be no above ground Western Harbour Tunnel tunnelling site in Birchgrove impacting local residents. This means we can avoid the temporary impacts of an above-ground tunnelling site, such as noise, dust, vehicle haulage, visual amenity, and loss of open space.

There will be no impact on Birchgrove Wharf, and its ferry operations.

We needed to install a permanent power supply in Rozelle and Lilyfield to enable our tunnel boring machines (TBMs) to tunnel under Sydney Harbour between Birchgrove and Waverton.

The power supply will also support the operation of Western Harbour Tunnel when it opens to traffic in 2028.

This work started in July 2024 and was completed in April 2025. The roads and pavements impacted by our work will be permanently reinstated in early 2026.

We acknowledge this work has been disruptive and we thank local residents for allowing us to work in their streets to complete this essential work.

We will always notify you before we start working near your property. All of our work notifications can be found here or on our notifications map.

For the latest information on work happening near you, please sign up for the weekly Inner West update email sent every Friday.

You can subscribe to these updates by clicking here.

If you have a question we have not answered here, contact us on 1800 931 189 or send an email to whtbl@transport.nsw.gov.au.

A Place, Design and Landscape Plan (PDLP) is an important stage of a project illustrating, in more detail than the Environmental Impact Statement (EIS), what a project will look like, how it contributes to places, what the buildings, bridges, and tunnels look like, what the landscape is like, where the paths and cycleways are, and how it all comes together with the road infrastructure.

A Place, Design and Landscape Plan provides the opportunity for the community to have a final look at the design of elements of a project before it is constructed.

The Western Harbour Tunnel (WHT) Place, Design and Landscape Plan (PDLP) outlines the design and landscape objectives of Western Harbour Tunnel and sets the framework to deliver great places for the community.

The WHT PDLP continues the design story that started on the Warringah Freeway Upgrade project PDLP, published in 2023, and approved in July 2024.

The WHT PDLP presents a quality design of motorway infrastructure in Sydney, offering a distinctive harbour crossing experience for future road users by weaving in the natural and cultural essence of the land into the final design.

The WHT PDLP will be presented in three parts, with each part including its own consultation period and key objectives.

WHT PDLP (Part 1) – Critical tunnel infrastructure and in-tunnel public art

WHT PDLP (Part 1) was completed in mid-2024 and in June 2025, the Plan was approved by the NSW Department of Planning, Housing and Infrastructure (DPHI).

WHT PDLP (Part 2) – Berrys Bay

Transport and WHT delivery partner, ACCIONA, are committed to creating a new foreshore parkland for the community and reconnecting people with Berrys Bay’s history, foreshore lands, and waters .

The draft PDLP is now closed for community feedback. All submissions received during the public exhibition period will be carefully reviewed and considered in shaping of the final design. The WHT PDLP (Part 2) - Berrys Bay will then be submitted to the Department of Planning, Housing and Infrastructure (DPHI) for approval, in accordance with the WHT project’s Conditions of Approval.

The future use and management of the Woodley’s Shed community facility - including outdoor and indoor spaces, will be the responsibility of North Sydney Council as part of its long-term operation and maintenance of the Berrys Bay foreshore parkland.

WHT PDLP (Part 3) - Cammeray Parkland

The third and final part of the WHT PDLP, Cammeray Parkland, will be for a new public park between Warringah Freeway and Cammeray Golf Course, Cammeray. This land is currently being used for the construction of Warringah Freeway Upgrade (WFU) and WHT.

We are excited to be able to return this open space to the community sooner than expected, now that it is no longer required for the Beaches Link project. Early planning work is now underway with the WHT PDLP (Part 3) - Cammeray Parkland, shaped with community and stakeholder feedback before being finalised.

WHT PDLP (Part 1) was approved by Department of Planning Housing and Infrastructure (DPHI) on 10 June 2025. It provides the design detail for elements of critical surface and in-tunnel infrastructure required to deliver the project.

The key elements in WHT PDLP (Part 1) include:

ventilation facilities

tunnel portals (entry and exits)

landscape design

tunnel interiors.

We understand the character and visual amenity of your local area is important, which is why community feedback has underpinned the design journey from the very start.

In early 2020 the Environmental Impact Statement (EIS) went on public display. High level urban design concepts were proposed for feedback and over 1454 submissions were received.

In January 2021, the Minister’s Condition of Approval was granted, and the project was approved to proceed.

The Warringah Freeway Upgrade project sought community feedback on its draft Place, Design and Landscape Plan in June-July 2023. This plan included visual amenity elements, such as urban and landscape design, freeway bridges, noise and retaining walls, and three active transport bridges across the freeway which emphasise Connection to Country.

The Warringah Freeway Upgrade PDLP was approved by the Department of Planning, Housing, and Infrastructure in July 2024.

The WHT PDLP has been developed using an integrated urban design approach, involving close collaboration with a broad, multidisciplinary project team. This included subject matter experts, key external stakeholders, North Sydney Council, and the State Design Review Panel (SDRP).

In March 2023, the SDRP was engaged, in accordance with the Minister’s Conditions of Approval for the project, to advise on the development of the PDLP. The SDRP comprises qualified, experienced, and independent professionals in fields including:

· Aboriginal and non-Aboriginal cultural heritage

· architecture

· landscape design

· urban design.

The SDRP was consulted on placemaking, artistic elements, architecture, heritage, urban and landscaping aspects of the design, and were engaged for both Warringah Freeway Upgrade and Western Harbour Tunnel projects’ PDLPs.

A SDRP was established to offer guidance and advice during the detailed design phase and the preparation of the PDLP, as required by Ministers' Condition of Approval, clauses E164 to E176.

The SDRP’s responsibilities include providing advice and recommendations for the development of the PDLP as well as providing advice on how the objectives apply to key design elements such as placemaking, architecture, heritage, urban and landscape design, and artistic aspects of this Critical State Significant Infrastructure (CSSI) project.

Interactive sessions with the SDRP for the WHT PDLP (Part 1) took place on the following dates:

SDRP 1 - 18/05/2023

SDRP 2 - 20/07/2023

SDRP 3 - 21/09/2023

SDRP 4 - 28/03/2024

Consultation with the SDRP for WHT PDLP (Part 2) - Berrys Bay took place on the following dates:

SDRP 5- 31/07/2024

SDRP 6 - 27/03/2025

SDRP 7- 08/05/2025

Under the advice of Cultural Capital, cultural facilitator Kyra Kum-Sing was engaged and endorsed by key stakeholder, the Metropolitan Local Aboriginal Land Council. Kyra identified a group of three Indigenous representatives. These Knowledge Holders consulted closely with the appointed artist who produced artwork for the tunnel. The artist and Knowledge Holders were part of a consultative co-design process with project architects.

A Design with Country objective has been incorporated into the project to ensure it responds to and supports the health and wellbeing of Country. This is reflected by tapping into the traditional reading of landscape features through the song-lines. These tell us of the creation time of the land through materials that mimic sandstone found on site - exposing the natural colours of Country and textures that draw on the natural environment and its history.

Chapter 2 of the WHT PDLP describes the context of the entire WHT project.

The Rozelle Interchange PDLP describes the surface features of the WHT project south of the harbour, specifically, the portal connection with City West Link.

Chapter 7 of the WHT PDLP describes the tunnel interiors, including the lining design and the tunnel ‘events’. The tunnel ‘events’ south of the harbour include designs on the tunnel lining as the tunnel passes under the suburbs of Rozelle, Balmain, and Birchgrove.

Urban design and landscape elements relevant to the southern part of the WHT project were consulted on during public display of the Rozelle Interchange's Urban Design and Landscape Plan (UDLP) in August 2020.

The Warringah Freeway Upgrade (WFU) project is responsible for building the structure and safety screens required for the Ernest Street bridge, however, the WHT PDLP will determine the landscaping. The landscape design on the bridge incorporates the finishes and structure of the WFU project to ensure consistency.

As part of the WFU project, Transport is also assessing the design of the western connection of the widened Ernest Street bridge to improve access for pedestrians and cyclists. Should an amended design proceed, the urban design and vegetation planting in the area will be carried out in accordance with the themes in the approved WFU PDLP.

The Western Harbour Tunnel PDLP (Part 1) was placed on public exhibition for four weeks between 31 July and 28 August 2024.

As part of WHT PDLP (Part 1), Transport for NSW (Transport) sought feedback on the visual amenity of a range of elements related to the tunnel’s critical in-tunnel and surface infrastructure, including the tunnel portals, façade of the Cammeray ventilation facilities, and landscaping design.

Some examples of aspects of the project we did not seek feedback on included the location and structural design of the ventilation facilities, noise walls, tunnel portals and other structures. These are determined by the critical functions of the facilities, requirements of mechanical and electrical equipment, and final design of the tunnel alignment.

A total of 266 submissions were received during the four-week PDLP display period.

Of these responses, 257 were provided by members of the community and nine responses were received from stakeholders including North Sydney Council.

All feedback received during the public display period of the WHT PDLP (Part 1) was taken into consideration and helped to shape the final design decisions for the PDLP. A summary of the feedback received, and Transport for NSW’s responses, was provided to the Department of Planning, Housing and Infrastructure (DPHI) for approval. DPHI approved the PDLP in June 2025. The final approved WHT PDLP (Part 1) is available to view on the WHT project website.

All feedback received during the public display period of the draft PDLPs (Part 2) - Berrys Bay, and the upcoming (Part 3) - Cammeray Parkland, will also be considered and will help validate the final design decisions.

Active Transport is outside the scope of WHT PDLP (Part 1), which focuses on the design of in-tunnel and surface infrastructure and landscaping design. This aligns with the project’s Environmental Impact Statement and planning approvals.

The landscaping aspects of the PDLP contributes to the project’s Tree Replacement Strategy.

Transport has developed a Tree Replacement Strategy in consultation with North Sydney Council, which outlines the principles for tree replacement including but not limited to potential planting locations and timing.

WHT PDLP is the next step in that process and details the landscape design plans for the project in association with the infrastructure, but not the work proposed in Berrys Bay or around Cammeray, which will form the next part of the WHT PDLP. This includes the location of existing vegetation, areas of vegetation to be retained and proposed planting and seeding details.

Our approach to replacing trees in North Sydney is in line with the planning conditions where replacement trees must be located on public land and prioritised within 500 metres of both the WHT and WFU project boundaries. As outlined in the Tree Replacement Strategy, there are limitations on the number of replacement trees that can be planted within 500 metres of the project boundary.

As a result of this limitation, North Sydney Council and Transport discussed the potential to identify alternative locations in the North Sydney LGA where replacement trees could be planted, outside the 500 metre requirement. Should locations outside the 500 metre requirement be identified and agreed with Council, Transport would seek approval from the Planning Secretary. Transport continues to work in partnership with Council to identify possible tree planting locations that align with our tree replacement principles.

You can find out more about the tree replacement strategy here.

Transport for NSW (Transport) understands the importance of trees to local communities and will be making every effort to maximise suitable plantings in the available area.

Transport has developed a Tree Replacement Strategy in consultation with North Sydney Council (Council), for Warringah Freeway Upgrade and Western Harbour Tunnel, which outlines the principles for tree replacement, including but not limited to, potential planting locations and timing. The strategy is available to view at nswroads.work/tree-replacement

WHT PDLP (Part 1) presents one stage of the tree replacement strategy and details the landscape design plans for the project in association with the infrastructure. It does not include the work proposed in Berrys Bay, or around Cammeray, which was presented in WHT PDLP (Part 2) - Berrys Bay and will be presented in WHT PDLP (Part) 3 - Cammeray Parland. WHT PDLP (Part 1) includes the location of existing vegetation, areas of vegetation to be retained, and proposed planting and seeding details.

The Tree Replacement Strategy is in line with the planning conditions where replacement trees must be located on public land and prioritised within 500 metres of the both the Western Harbour Tunnel and Warringah Freeway Upgrade project boundary. As outlined in the Tree Replacement Strategy, there are limitations on the number of replacement trees that can be planted within 500 metres of the project boundary.

As a result of this limitation, Council and Transport are discussing the potential to identify alternative locations in the North Sydney Local Government Area where replacement trees could be planted, outside the 500 metre requirement. Should locations outside the 500 metre requirement be identified and agreed with Council, Transport would seek approval from the Planning Secretary.

Transport continues to work with Council to identify possible tree planting locations that align with its tree replacement principles and ensure the strategy’s commitments are met. Transport will keep the community informed as the project continues, and tree replacement activities take place.

The Western Harbour Tunnel (WHT) project's ventilation building in Cammeray will not be constructed underground. Improved conditions for construction, an acceptable location identified aboveground, and significantly reduced costs determined the decision to build the ventilation building aboveground, as part of the WHT EIS which was approved in January 2021.

A ventilation outlet is used to disperse air from the motorway tunnels high into the atmosphere, away from the ground plane and surrounding buildings. Each outlet is custom designed considering local tunnel air flows, terrain, surrounding buildings and weather to ensure effective dispersion under all conditions.

Construction of one WHT ventilation outlet was included in the scope for the Rozelle Interchange project. This ventilation outlet is one of three-cylinder structures located at the Rozelle Parklands, with the remaining two ventilation outlets now in operation to service the WestConnex M4 and M8 tunnels at the Rozelle Interchange.

Urban design and landscape elements relevant to the southern part of the WHT project were consulted on during public display of the Rozelle Interchange's Urban Design and Landscape Plan (UDLP) in August 2020.

The second ventilation outlet for WHT will be located within the Warringah Freeway corridor, to the north of Ernest Street in Cammeray and is yet to be built.

There has been no change made to the size or location of the ventilation facilities in Cammeray as those elements were outside the scope of WHT PDLP Part 1 consultation.

The size, scale and structural material of the ventilation facilities is determined by their function, the requirements of the mechanical and electrical equipment, and final design of the tunnel alignment.

Tunnel ventilation systems generally work most efficiently and effectively when the ventilation outlet is positioned near the exit ramp, which is why the ventilation facilities are located near the tunnel exit ramps in Cammeray and tunnel exit ramps at the City West link, Rozelle.

The location of the ventilation facilities within the Warringah Freeway was assessed in the project’s Environmental Impact Statement and approved by the Minister for Planning and Public Spaces in January 2021, as part of the Minister’s Conditions of Approval.

Planting around the ventilation facilities has been maximised, including the provision of tree species that will provide future screening of the structures, from the roadway and public domain.

The draft design of the ventilation facilities’ facades at Cammeray put on display for consultation, including the colours selected, went through a process of detailed reviews with the State Design Review Panel (SDRP), as well as in-depth consultation with key stakeholders as part of the detailed design process.

The project’s urban designers which included Local Knowledge Holders and Aboriginal artist Dennis Golding, collaborated on a design which incorporates Connection to Country while maintaining the functional requirements of the buildings.

The façade material and colours have been purposefully selected to minimise visual bulk and mimic and harmonise with the surrounding landscape, including with the golds and bronzes of the nearby Ernest Street bridge, being constructed by the Warringah Freeway Upgrade project.

Tunnel ventilation systems generally work most efficiently and effectively when the ventilation outlet is positioned near the exit ramp. This is why the ventilation outlets for modern tunnels are located near the tunnel exit ramps.

The location, size and height of the ventilation tunnels were determined as part of the air quality assessment carried out for the project’s EIS. We build the ventilation outlets in accordance with the air quality assessment and therefore the location, size and height of the outlet is not subject to the PDLP consultation. However, the way the ventilation outlet looks is subject to the PDLP and community feedback is welcome.

The ventilation outlets for WHT will not be filtered. The project’s ventilation system will be built to meet strict air quality standards using state-of-the-art ventilation and tunnel design.

No road tunnels in Australia use a tunnel filtration system.

In NSW we have an Advisory Committee on Tunnel Air Quality, chaired by the NSW Chief Scientist and Engineer, which consists of a range of experts in fields related to road tunnels, air quality and human health. This includes the NSW Chief Health Officer and an independent, international air quality expert.

The Committee has released a report in relation to road tunnel air quality which found emissions from well-designed road tunnels cause a negligible change to surrounding air quality, and as such, there is no discernible health benefit for surrounding communities in installing filtration and air treatment systems in the tunnels.

To find out more about Air Quality Control, visit our website here.

Submissions for the draft PDLP are now closed.

Visit the WHT PDLP for Berrys Bay webpage here where you can learn more about the WHT PDLP (Part 2) - Berrys Bay and the PDLP process.

The project team will review and consider all feedback received during the consultation period. The feedback will help validate the design decisions and opportunities outlined within the PDLP and the future parkland. We will submit the draft WHT PDLP (Part 2) - Berry Bay along with the community submissions received and our responses, to the Department of Planning, Housing, and Infrastructure (DPHI) for its assessment and approval.

We will keep the community informed as the project progresses.

Construction commenced in June 2025 with the parklands will open to the public ahead of the tunnel opening to traffic in 2028. We will keep the community updated on construction of the project as it progresses.

To stay up to date with the construction of the Berrys Bay foreshore parkland by visiting the Berrys Bay page on our portal here.

Celebrating the history of Berrys Bay means recognising and sharing the stories, cultures, and experiences of the people who have lived on and cared for this land — especially the Traditional Custodians, the Cammeraygal People.

The Cammeraygal lived on Country for thousands of years. They had a deep spiritual and physical relationship with the land and sea, using the area for fishing, hunting, gathering bush foods, and holding cultural ceremonies. Berrys Bay, with its sheltered waters and access to rich marine life, was an important site for food, travel and community.

Transport understand that Berrys Bay has been significant in the history of Sydney since first contact. Layered across time, the land at Berrys Bay has been used strategically due to its access to calm tidal waters on Sydney Harbour.

The first wharves were established in the 1820s and over the next 200 years would follow a whaling station, coaling depot, timber yard, sandstone quarry, oil depot, torpedo station, quarantine boat depot, distillery, boat building and ship repair yard.

In March 2021, community members were invited to apply to be part of the Berrys Bay Community and Stakeholder Working Group (CSWG) alongside representatives from the NSW Government and North Sydney Council.

The purpose of the CSWG was to help determine the optimal vision and design of Berrys Bay and to consider perspectives and preferences across the community and the NSW Government to provide the best outcome for both the local and wider community.

This collaborative forum enabled a fair, sustainable, productive and sensitive outcome. It provided advice and assisted the Berrys Bay project team in understanding the current and future needs of the local community.

The Berrys Bay master plan development was informed by the outcomes of the CSWG meetings.

The project team thank all members of the Working Group for their time and expertise shared, contributing to the future of Berrys Bay for future generations.

In 2025, The Minister for Environment and Heritage confirmed the State Heritage Register listing was to include Berrys Bay Precinct (Carradah Park, Balls Head Road, Waverton). For further details please contact the NSW Department of Climate Change, Energy, the Environment and Water (DCCEEW) or visit Heritage NSW website.

Listing a place on the State Heritage Register provides several benefits aimed to preserve and protect the heritage of significant sites. Benefits include:

conservation requirements be considered for any proposed changes planned at the site

access to government grants for ongoing maintenance, if eligible

ensures future development proposals are carefully assessed to avoid impact to the site’s significance

heritage status attracts tourism, potentially boosting local businesses through visitation, events and activities

recognition of significance leads to increase public awareness and boosting a community’s sense of pride

helps preserve sites for future generations making learning and educational opportunities possible.

The derelict buildings are significant and iconic to the Waverton peninsula at Berrys Bay but are not listed as heritage items. This means the cultural importance and architectural value of the buildings can be harnessed, reimagined and celebrated into a new community pavilion. The new community pavilion at Berrys Bay will be inspired by form, scale and material finish of the Woodley’s Shed main building.

Transport for NSW in partnership with North Sydney Council’s visions for the new community pavilion at Berrys Bay includes:

an open-air gathering place for community which reimagines and reinterprets the iconic shape, materials and building elements of the former Woodley’s Shed main building, including the bold sheet metal lettering, roof line and building form

the building design reflects the legacy of boatbuilding which has occurred on the site throughout time and marine life, with the use of timber ‘ribs’ and ‘slats’ to define the community building exterior. There will be opportunities to further integrate both Aboriginal and western boat building forms and techniques as the design develops.

Further details are yet to be determined through ongoing design work with North Sydney Council and community feedback period in response to the draft PDLP (Part 2) – Berrys Bay.

The vision for the new community pavilion has been developed considering community feedback and ongoing consultation with North Sydney Council.

North Sydney Council and Transport have confirmed the requirements for the new community pavilion and community building which sits within.

It is proposed that the new community building will include:

An enclosed space with ability to host up to 80 people in a banquet arrangement – perfect for community groups

Future provisions for a kitchen facility, office / administrative room and future connection points for services like power and water

Provisions for public toilets with a family accessible bathroom which can be independently secured, also available for use by park users

The community building sits within the reimagined Woodley’s Shed community pavilion, a location by the water’s edge which maximises natural light and harbour views

It is proposed that the new Woodley’s Shed community pavilion will:

Provide a large covered open space able to cater for various gatherings and community uses

Enable flexibility, connectivity and permeability to continue when the community building is closed to the public (in use by others).

Include salavaged materials and finishes which reflect the former main building of Woodley’s Shed, the centre of decades of boatbuilding and ship heavy maintenance since 1908

A design which also maximises harbour views and natural light, minimising heating and cooling requirements for both the outdoor and indoor community spaces

Opportunities for shade, seating and planting

Previous community feedback received during the Master Plan consultation in 2022 was mixed on the potential gathering and recreation uses for sites in Precinct 2 (location of former Woodley’s Shed).

Suggestions received from the community in 2022 during the initial master plan consultation included:

Community centre, with cafe or restaurant, also available for meetings

Creative workspaces

Museum

Performance space and/or art gallery.

The design has been developed in accordance with the following design principles and designed iteratively in consultation with North Sydney Council and the State Design Review Panel.

The design journey is detailed within the PDLP, please visit the PDLP webpage for more information regarding Berrys Bay foreshore parkland.

As a summary, the design principles are:

Designing with Country

Express the natural and social layers that comprise Country through genuine consultation that leads to design outcomes that speak to place and living culture.

Create an inclusive and safe space

Design a welcoming, accessible, and universally inclusive environment that caters to all ages, abilities, and cultural backgrounds.

Express the layers of history

Berrys Bay has a long history in pre- and post-colonial Sydney. Acknowledge and interpret this rich history of the site, from Aboriginal occupation to boat-making and oil storage, as captured through historic accounts and community stories.

Rejuvenate pre-industrial vegetation and improve biodiversity

Heal the landscape with endemic plants that create habitat for native fauna.

Sustainability

Embed sustainability considerations into the design, delivery and operation of the project in order to minimise environmental and social impacts.

Taking into consideration the feedback received during consultation on the draft master plan, the following key design changes were adopted:

Incorporation of more natural, sustainable and locally responsive ground finishes including crushed sandstone

Additional trees, vegetation and seating to increase habitat and create shaded and pleasant places for recreation

Removal of the foreshore common circular path with a more organic shaped pathway to increase the area of usable open space

Indication of potential location for kayak and small watercraft storage

Reconfiguration of the foreshore pathways in front of a reimagined Woodley’s Shed ensuring generous pedestrian movement along the water’s edge

Retention of slipways to facilitate access to the water for kayak and small non-motorised watercraft.

The key changes which are detailed via the draft Place, Design and Landscape Plan includes:

Deconstruction and reimagining of Woodley’s Shed main building as a community pavilion with indoor and outdoor covered spaces

Removal of the derelict former refinery Administration Building to improve accessibility to and from the site, considering significant level changes and visual connection to the water and harbour views

Focus water access for non-powered watercraft at Slipway 4, including the removal of tidal steps and jetty option

Improve accessibility across the parklands and foreshore with changes to pathways including service vehicle access to/from Balls Head Road

Openings through the Bund Wall to provide visual connections, enabling movement betweenplayground and family picnic areas

Iterative design of the playground facilities following co-design workshop with children and young people

Ensure safe compliant access to the Sydney Water assets at Berrys Bay

Maximise tree canopy with native planting areas

Rationalise number of parking spaces due to site constraints.

Throughout the design process, our ongoing consultation with stakeholders including North Sydney Council through the development of the Functional Brief, funding considerations including ongoing operation and maintenance costs for Council has meant there have been changes to the design.

This area is owned and maintained by North Sydney Council, and we are collaborating on the future connections to the area as part of the Berrys Bay project delivered as part of Western Harbour Tunnel.

North Sydney Council has made the area more accessible by the integration of boardwalk path and upgrades to footpaths and steps to enhance existing connections to ‘Council Beach’ and the former Quarantine Boat Depot.

North Sydney Council's endorsement of the Master Plan (2022) indicates a commitment to the overall enhancement of the Berrys Bay area including Precinct 3 - former Quarantine Boat Depot.

Materials in good condition for salvage and reinterpretation include:

Woodley’s Shed – select metal sheeting panels,facade lettering “WOODLEYS PTY LTD and former shipyard equipment including disused cable winch.

By incorporating salvaged materials into the reimagining of Woodley’s Shed as a new community pavilion, we can reduce waste and champion sustainability, but also giving the space a unique, character-rich identity linked to the maritime and industrial past of the site. This approach also aims to foster creativity, community engagement, and environmental stewardship, all while honouring the history of the materials and the place itself.

Transport for NSW (in partnership with North Sydney Council’s) visions for the new community pavilion includes:

an open-air gathering place for community, connected to the waterfront and iconic views of Sydney Harbour which reimagines and reinterprets the iconic shape using materials and building elements of former Woodley’s Shed main building, including the bold sheet metal lettering, roof line and building form

accessible and inclusive public amenities like bathrooms and a separate family accessible bathroom

indoor community space with future provisions for a small kitchen facility and services room.

While consultation is ongoing, it is expected that North Sydney Council will have care and control of the future community pavilion and parkland at Berrys Bay including a role in developing a Plan of Management and community programs (including art, wellbeing and learning) which supplement work carried out at the nearby Coal Loader Centre for Sustainability and connects with other Council sites such as the former Quarantine Boat Depot.

The detail design for Berrys Bay went on public display through the WHT PDLP (Part 2) - Berrys Bay between 28 July 2025 - 24 August 2025.

The draft PDLP is now closed for community feedback. All submissions received during the public exhibition period will be carefully reviewed and considered in shaping of the final design. The WHT PDLP (Part 2) - Berrys Bay will then be submitted to the Department of Planning, Housing and Infrastructure (DPHI) for approval, in accordance with the WHT project’s Conditions of Approval.

Ensure you are subscribed to the WHT Berrys Bay email distribution list to be kept up to date as the project progresses. Click here to subscribe.

Site establishment started on 23 June 2025 with the parkland open to the public ahead of the tunnel opening to traffic in 2028. We will keep the community updated on construction of the project as it progresses.

The WHT project approval allows site establishment and other work not subject to the PDLP to continue. The draft PDLP will be open for community feedback in July 2025 and approval by the NSW Department of Planning, Housing and Infrastructure (DPHI) on the final PDLP will follow.

Early works underway include establishing a temporary construction work site with worker facilities, security and fencing, removing temporary structures, removing derelict buildings, carrying out environmental remediation, vegetation removal and trimming, surveying and sampling the ground/marine conditions, and undertaking earthworks. These works are essential to make the site safe and ready for the next stage of construction works.

Installing landscaping and other select parkland permanent features will begin once the draft PDLP is approved, ensuring the final design reflects community views.

During construction, a range of temporary access changes are required to conduct work safely and ensure our impact on the local community is minimised.

Temporary access changes in place include:

temporary closure of on-street parking at the cul-de-sac of Balls Head Road, Waverton

temporary changes to the pedestrian access along the foreshore between Balls Head Road and Carradah Park

temporary changes to the pedestrian access to Council beach via the former Quarantine Depot including a temporary bridge

There were a few key additional actions required before finalising the draft PDLP – Berrys Bay, including additional consultation with North Sydney Council.

These included:

carry out a modification to the Western Harbour Tunnel planning approval, including community consultation to change the proposed construction methodology to include tunnel boring machines, which meant the foreshore land at Berrys Bay was no longer needed as a tunnel construction support site

the Modification approval was received in January 2024

further site investigations and inspections of existing derelict structures in and around the site

completion of the Heritage Impact Assessment to ensure the integration of heritage items

carry out the master plan process with North Sydney Council in 2022-2023 including community consultation to plan for the future of the area

receive endorsement from North Sydney Council to formally include Precinct 2 into the future planning for the area, including details around the reimagined Woodley’s Shed as a community pavilion,

undertake design work to integrate Precinct 2 into the parkland plans and landscape design including consultation with the State Design Review Panel

There are two ways to learn more about the Western Harbour Tunnel and Berrys Bay work underway. The project website is up to date with interactive maps, construction work notifications, plans, documents and reports. Visit the project page here.

Alternatively, the project team will be happy to talk with you over the phone or via email to answer any questions.

Each quarter, the project team hosts community information sessions (online and face to face option) regarding upcoming works for targeted local residents and stakeholder groups which are useful.

The Western Harbour Tunnel team is made up of project members from Transport and ACCIONA. We are available to answer questions, collect feedback and manage complaints. Our contact information is:

Phone: 1800 931 189

Email: whtbl@transport.nsw.gov.au or wht@acciona.com

Mail: Transport for NSW

Locked Bag 928,

North Sydney NSW Australia 2059

The Berrys Bay Connection to Country Principles (WSP, December 2022) outline a range of activities and processes that the Berrys Bay team have applied in regard to Aboriginal engagement and involvement. Recommendations and actions within are being delivered in our detailed design and construction planning work for the future of Berrys Bay foreshore parkland.

Transport for NSW and ACCIONA have successfully removed over one hundred pieces of derelict maritime structures (sunken jetties/piers and piles/supports) located within the water to enable safe work zone for the seawall rectification work.

This work will also improve navigation in the water once Berrys Bay foreshore parkland is transformed and open for community to enjoy.

The integration of the reimagined Woodley’s Shed into the Berrys Bay parkland design enables a continuous foreshore pathway through Precinct 2, removing the need for the previously proposed boardwalk and jetty. Instead, we’re focusing on improving access to the water’s edge, including a consolidated access point for launching non-powered watercraft like kayaks and paddleboards at the reconstructed Slipway 4.

This approach opens up more of the foreshore for community including views of the harbour and ensures the area remains flexible, accessible, and easy to maintain into the future.

In November 2024, North Sydney Council endorsed the formal incorporation of Woodley’s Shed (Precinct 2) into the Berrys Bay foreshore parkland project, creating a once in a generation opportunity to reimagine the disused former industrial land and buildings which have reached the end of their useable life into new community space.

Originally, Woodley’s Shed and other derelict buildings were going to be fenced off for public safety. The opportunity to integrate the whole precinct into the Berrys Bay parklands can now be realised, delivering a high-quality outcomes for the community as a result of the endorsement.

Unfortunately, the Woodley’s Shed buildings, workshop and annexes and other structures are significantly dilapidated and structurally unsound.

The aging building has surpassed its usable lifespan and is being reimagined to provide a flexible usable community pavilion to meet modern standards.

Select building materials will be carefully salvaged and reused including the iconic building façade sign. Photo archival recording has also been completed and will be shared with North Sydney Council’s Stanton Library

Unfortunately, the buildings at Berrys Bay, including the former refinery Administration Building, are dilapidated, unsafe and beyond their useable lifespan after decades of shipbuilding activities and a period of disuse.

The Administration building would require significant renovation to remediate sufficiently for use, and there is currently no water or sewer connections. Now Transport has committed to providing a new building for North Sydney Council to operate and maintain, the existing administration building can be removed to improve accessibility to the parkland and community pavilion.

During the tender process for Stage 2 of the project, different designs and methodology were considered to ensure the best design and outcomes are considered for the project, community and environment. ACCIONA submitted an alternative methodology of using tunnel boring machine (TBMs) to tunnel beneath the Sydney Harbour seabed. This design was assessed and selected as it provides the best overall value for the people of NSW and minimises impacts on the local community and environment.

The specialised TBMs will each tunnel for about 1.5km from Birchgrove to Waverton including under the Sydney Harbour seabed, connecting the northern and southern ends of the project. Using TBM methodology means we no longer require temporary construction sites at Yurulbin Point or Berrys Bay, and cofferdams are no longer required at Yurulbin Point or Balls Head. This also means that no dredging will be required and there will be no impact to Birchgrove Wharf.

Transport has determined the TBM methodology to be the best overall solution to deliver Stage 2 tunnelling beneath Sydney Harbour.

A design using a TBM was originally considered as part of the EIS. At the time, an Immersed Tube Tunnel approach was assessed as being the most suitable option due to the nature of the project as well as the local ground conditions beneath Sydney’s Harbour.

Since the development of the concept design in 2017 and the proposed reference design in 2018 for the project, technology and the market have evolved. Other projects have recently proven the efficiency and success of using a TBM to tunnel beneath Sydney’s Harbour.

As this methodology was not fully assessed and approved during the EIS, the project sought approval to use the TBM methodology through a modification, which the community was consulted on in 2023. This is a standard process when making changes to an approved major project.

The Department for Planning, Housing and Infrastructure (DPHI) approved the Modification to the Western Harbour Tunnel project in January 2024.

Since the development of the concept design in 2017 and the proposed reference design in 2018 for the project, technology and the market have evolved. Sydney Metro has recently proven the efficiency and success of using a TBM to tunnel in varying ground conditions beneath Sydney’s Harbour.

A tunnel boring machine, often referred to as a TBM, is a machine used to excavate tunnels.

At the front of the TBM is a cutter head which excavates the ground. As the tunnel advances, precast concrete segments are installed to support and permanently line the tunnel.

The excavated material is mixed with slurry and transported to a Slurry Treatment Plant. The excavated material is separated from the slurry and prepared for recycling or disposal.

TBMs are used worldwide and in NSW as a tunnelling solution. Using a TBM significantly reduces our surface impacts. By launching the TBM completely underground, it removes the need for construction sites and cofferdams at Birchgrove and Waverton. It also removes the need for dredging in Sydney Harbour.

TBM will be used for a 1.5km section of the tunnel beneath Sydney Harbour and will lead to improved environmental and community outcomes including:

• reduced number of temporary construction sites (Berrys Bay, Yurulbin Point, Sydney Harbour sites no longer required)

• with no tunnelling works from Berrys Bay, the Berrys Bay master plan will be delivered earlier

• no dredging of Sydney Harbour

• no removal of Sydney Harbour sediment near Balls Head

• no impact to existing harbour operations (HMAS Waterhen, VIVA Energy, ferries, recreational watercraft)

• Birchgrove Ferry Wharf no longer impacted

• no cofferdams at Yurulbin Point or Balls Head

• no temporary relocation of MV Cape Don

• temporary relocation of moorings at Berrys Bay no longer required

• upgrade and utilisation of moorings at Snails Bay no longer required

The TBMs will be assembled in an underground launch chamber that has been excavated under Birchgrove. No additional dive or launch sites are required for the TBMs.

Each piece of the machine will be transported on a truck to the Western Harbour Tunnel entry, which is already excavated as part of the Rozelle Interchange and driven to the underground launch chamber.

The TBM launch chambers are an area in the tunnels underground, where the TBMs are assembled to start tunnelling under Birchgrove towards Waverton. Each launch chamber will consist of an underground excavation area of around 120 metres long, 21 metres wide and about 28 metres tall, and is built within the tunnel alignment in Birchgrove.

More information about the launch chambers can be found in our fact sheet.

The majority of the launch chamber used to assemble and launch the TBMs, does not get filled in and instead becomes part of the operational and permanent road tunnel.

Both TBMs will arrive to Glebe Island by October 2025.They will be delivered underground in pieces and assembled in the launch caverns. TBM excavation is expected to commence around mid-2026.

The Department for Planning, Housing and Infrastructure (DPHI) approved the Modification to the Western Harbour Tunnel project in January 2024.

About the Modification

The Modification Report was submitted in July 2023, proposing to amend the Western Harbour Tunnel project granted planning approval in January 2021.

The approved Modification means that we are changing the construction methodology for tunnelling under the Sydney Harbour between Birchgrove and Waverton from an Immersed Tube Tunnel to using tunnel boring machines (TBMs). This change will reduce construction impacts on the community and environment by:

not dredging in Sydney Harbour

reducing the overall number of construction support sites by removing the need for construction support sites at Yurulbin Point, Berrys Bay, White Bay North and Victoria Road

removing the need for cofferdams in Sydney Harbour at Birchgrove and Balls Head

removing impacts to Birchgrove Ferry Wharf and ferry services

reducing impacts to ferries and boats on Sydney Harbour.

Approval of the Modification also means there will be a new construction support site at Emu Plains and changes to our existing support sites at the City West Link Portal, Glebe Island and Ridge Street, North Sydney.

All other construction activities and elements of the approved project not included in the Modification Report will continue to proceed as planned.

As with any major infrastructure project of this scale, the approved changes are subject to the Minister’s Conditions of Approval. You can learn more about these conditions and view the full Modification Report here on the Department of Planning and Environment’s Major Projects portal.

A tunnel boring machine (TBM) has the capacity to tunnel through the rock bed and marine clay beneath the harbour as opposed to dredging. This removes the need to manage harbour sediment and subsequent disposal to landfill or offshore.

Transport has determined the TBM methodology to be the best overall solution to tunnel beneath Sydney Harbour. Transport remains committed to minimising impacts to the community and the environment.

Dredging is a relatively common activity within New South Wales ports and coastal waters, with specialised contractors and equipment designed to meet project and environmental requirements in a variety of conditions. What we were planning is similar to previous work already carried out on many projects within Sydney Harbour, including at Garden Island in 2019.

ACCIONA submitted an alternative methodology of using a tunnel boring machine (TBM) to tunnel beneath the Sydney Harbour seabed. This design was assessed and selected, as part of their overall solution, which provides the best value for the people of NSW and further minimises impacts on the local community and environment.

Following a rigorous assessment of the local ground conditions, a slurry TBM has been selected as the most appropriate type of TBM for the Western Harbour Tunnel.

Excess material or material that cannot be reused on the project will be taken to an approved location that can receive the material. Some material may be suitable for use on other projects.

The two slurry treatment plants (STPs) for each of the two TBMs will be located in the ventilation caverns under Rozelle. This section of the tunnel was excavated as part of Stage 1 and widened by Stage 2.

Western Harbour Tunnel is using two TBMs to tunnel the southbound and northbound road tunnels. They will not bore alongside each other simultaneously. It is standard practice that the TBMs are spaced out meaning one will start first and bore at a distance ahead of the other.

The TBMs used for the Western Harbour Tunnel are some of the biggest in the world. The TBMs are expected to each be about 15.7m in diameter, however, the final width may be reduced through the detailed design process. The TBMs are about 120m in length.

Our specialised TBM machines will each tunnel for about 1.5km from Birchgrove to Waverton including under the Sydney Harbour seabed, connecting the northern and southern ends of the project.

Our specialised TBM machines will tunnel for about 1.5km under from Birchgrove to Waverton including under the Sydney Harbour seabed, connecting the northern and southern ends of the project. The TBM methodology has been adopted as an alternative to using the originally planned Immersed Tube Tunnel construction method. With the expected geology under Sydney Harbour, the TBM method is efficient and has a reduced impact on the environment and community.

The majority of the Western Harbour Tunnel will be excavated using electrically powered machines known as roadheaders, as originally planned, due to their suitability for tunnelling through land based geology. Roadheaders were however found to be less effective for tunnelling beneath Sydney Harbour, where there are different ground conditions so tunnel boring machines (TBMs) will be used to excavate the section of the tunnels between Birchgrove to Waverton.

Transport and ACCIONA are committed to creating opportunity for local businesses and suppliers on this major project. In collaboration with industry, the delivery of Western Harbour Tunnel will include the development and implementation of a business capability program to increase the capability and capacity of ANZ Small and Medium Enterprises and social enterprises.

Transport for NSW is confident our work can be completed without posing significant risk to the marine environment or users of the harbour.

The Western Harbour Tunnel and Warringah Freeway Upgrade Environmental Impact Statement (EIS) is based on expert peer-reviewed advice, past experience and world’s best practice.

We understand Dawn Fraser Baths is an important swimming location for the community.

The Baths will remain open throughout construction, and there will be no direct impacts on the Dawn Fraser Baths while we build the Western Harbour Tunnel.

TBM machines can only move in one direction. Once we have completed tunnelling the TBM section of the project, the TBMs will be driven into a ‘receival chamber’. We will salvage as much of the machine as possible, removing it in pieces back through the entrance to the tunnel at Rozelle.

The cutterhead and shield of the TBMs cannot be safely salvaged and will be buried underground and encapsulated in the receival chamber. This is a normal process when tunnelling using the TBM methodology, and all safety and environmental measures will be carried out to ensure it is safely buried. Burying the cutterhead and shield of the TBMs mean we do not need to create an above-ground construction site to remove them, which would have significant impacts on the local community.

As the TBM methodology was not fully assessed and approved during the EIS, we sought further approval from the NSW Minister for Planning to modify the Conditions of Approval (CoA), in accordance with the requirements of Division 5.2 of the Environmental Planning and Assessment Act 1979.

From 19 July to 15 August 2023, we invited the community to have their say on proposed changes to the way we build the Western Harbour Tunnel under Sydney Harbour.

We displayed the Modification Report which outlined a modification to the approved Western Harbour Tunnel project to change the construction methodology for crossing under Sydney Harbour between Birchgrove and Waverton from the approved Immersed Tube Tunnel (IMT) method to Tunnel Boring Machines (TBMs).

The Department for Planning, Housing and Infrastructure (DPHI) approved the Modification to the Western Harbour Tunnel project in January 2024.

We continue to work closely with councils, communities and stakeholders to ensure the best possible outcomes for community once we have finished our construction work.

The project’s Place, Design and Landscape Plan (PDLP) is being delivered in three parts. To learn more about the PDLP process, please visit the PDLP project page and opportunities to have your say.

As per E178 in the Conditions of Approval (CoA), the PDLP must be prepared by a suitably qualified and experienced team, in consultation with relevant councils, the community, affected landowners and businesses.

The change in methodology means we no longer require a construction site at Berrys Bay. As a result, there will be no Western Harbour Tunnel construction work activities at this location, meaning we can avoid the temporary impacts of an above-ground tunnelling site, such as noise, dust, vehicle haulage, visual amenity and loss of open space. There will be no impact to harbour operations or the Coal Loader Sustainability Centre and no temporary relocation required for the MV Cape Don.

Our objective is to ensure there are no buildings at risk of damage from vibration and settlement impacts while we are carrying out our work.

The new TBM method does not pose additional risk to properties from vibration.

As is the standard process for tunnelling, we will offer eligible properties in close proximity to the tunnel alignment and any settlement or vibration-intensive works a free property condition survey. While we are building, we will monitor noise and vibration to make sure it meets the appropriate guidelines.

Early work for Stage 2 commenced on 22 May 2023 and includes further geotechnical investigations, archaeological investigations and more. For more information, view the notifications for work both north and south of the Harbour here.

The project reached a major milestone with the start of roadheader tunnel excavation on the north side of the Harbour from late November 2023 at Cammeray. Read our Start of Tunnelling notification for more information. To learn more about our construction activities and how we manage any potential impacts from our tunnelling activities, please refer to our Stage 2 fact sheets.

We will contact residents before any work starts in their area. Community information sessions will be scheduled before tunnelling starts in each suburb along the alignment.

Learn more about the construction work in progress at Berrys Bay below or at the website.

In the areas of the tunnels where we are using roadheaders, excavation is completed in two phases.

The first phase involves excavation of the tunnel roof using a roadheader, an excavation machine that cuts rock in a circular motion suitable for creating the arched shape cavern required for road tunnels.

The crew excavate between 1-5 metres at a time (depending on the design), before installing ground support into the tunnel walls, including rock bolts (metal rods) and shotcrete (sprayed concrete). We generally excavate around 20-25 metres of rock per week.

The second phase of tunnel excavation involves removing the tunnel floor using a roadheader or rock hammer.

When using a roadheader, this work progresses much quicker than the first phase, at approximately 15-25 metres per day. On some occasions, we will need to use a rock hammer to excavate the floor. This work will be restricted based on vibration levels in compliance with project approvals.

Tunnel support activities include drilling, adding extra rock bolts, profiling, installing drainage and laying a new road pavement.

The project has approval to carry out tunnelling activities (including support activities) 24 hours per day, seven days a week. The first stage of tunnel excavation involves cutting the roof of the tunnel using a roadheader. The crew cut forward between 1 and 5 metres at a time (depending on the design) before installing ground support which includes rock bolts (metal rods) and shotcrete (sprayed concrete). We generally progress this work at approximately 20-25 metres per week. The second stage involves the removal of the tunnel floor using a roadheader or rock hammer. When using a roadheader, the removal of the tunnel floor progresses at a much quicker rate of approximately 15-25 metres per day.

To keep up to date with tunnelling activity between Cammeray to Waverton, visit our North Sydney tunnelling page here.

We understand there is concern about the potential for vibration and settlement impacts from tunnelling works. Ground movement does not necessarily result in property damage, in fact it is highly unlikely. Buildings experience ground movement naturally through environmental changes such as seasonal climate variations, vegetation (tree roots), structural effects (different building types of age of construction) or ground effects (reactivity to soil).

Properties above the final tunnel alignment (and within 50 metres of the alignment, in line with planning approvals) will be offered a property condition survey. Even though it is highly unlikely for any damage to occur from our tunnelling, Transport encourages anyone who is eligible for a property condition survey to take up this offer following confirmation of the final alignment.

If your property is located within 50 metres of the tunnels you will be offered a property condition survey (PCS) before and after construction. The survey is free and will ensure there is a clear record of your property’s condition. In the unlikely event damage is caused by our construction work, it will be repaired at no cost to you.

Construction of these tunnels will continue to follow well-established methods used on other major tunnelling projects in the Sydney region. They will be built safely, and in line with the project’s planning approvals.

All properties within 50 metres of the tunnel are eligible for a PCS both before and after construction of the tunnels. The project strongly recommends property owners accept the offer to have one completed. The PCS is free to residents and will provide a photographic baseline for comparison if you have concerns about property damage that you believe was caused by construction activity. In the unlikely event that any damage is caused by our construction work, rest assured it will be repaired at no cost to you.

You may have already undergone a PCS or received several offers from other projects in the area, we strongly urge you to accept this offer for each individual project. Accepting these offers ensures that your property is documented in the construction phase for each project.

Property condition surveys involve a visual inspection of the interior and exterior of a property to document its condition before construction work takes place nearby, in accordance with the Australian Standard 4349.1 Inspection of Buildings.

Property condition surveys are completed at no cost to you, and at a date and time that is convenient to you. The property owner (or nominee) will need to be present to grant access to the property.

Inspections typically take around two to three hours to assess and photograph the internal and external condition of the building/s, depending on the size and features of your property. The outcomes of the inspection will be detailed in a property condition report, and you will be supplied with a copy. Transport and ACCIONA will also keep a copy.

The report will also include photographs to provide an accurate record of the current condition of the property and will record any noticeable defects. Inspections are scheduled to take place during daylight hours to accurately record the condition of the property’s exterior.